Explore our range of high-quality machines for veggie processing. From meat grinders to sausage separators and smokehouses, we offer tailored solutions for your needs.

The Bastra Cooking kettle 2000PLUS is your solution for versatile cooking. Choose between electric, gas, oil, or steam heating and rely on high-quality chromium-nickel steel with efficient all-around insulation – ideal for capacities from 200 to 1200 liters.

Ready for your perfect cooking kettle? Get advised now!

The KDN cooking kettle, made of chromium-nickel steel (1.4301) with a glass-bead blasted surface, offers precise temperature control from 50–220°C. Its glycerin double jacket and electric direct heating with thermostat make it ideal for hygienic cooking in sizes of 50, 120, or 150 liters.

Excited for perfect cooking results? Contact us!

The KDN 200 is a mobile cooking kettle made of chromium-nickel steel (1.4301) with a brushed surface and a 200-liter capacity. With its double-walled construction, full insulation, and casters, it is ideal for flexible and hygienic use in your kitchen.

Ready for more efficiency? Get advised!

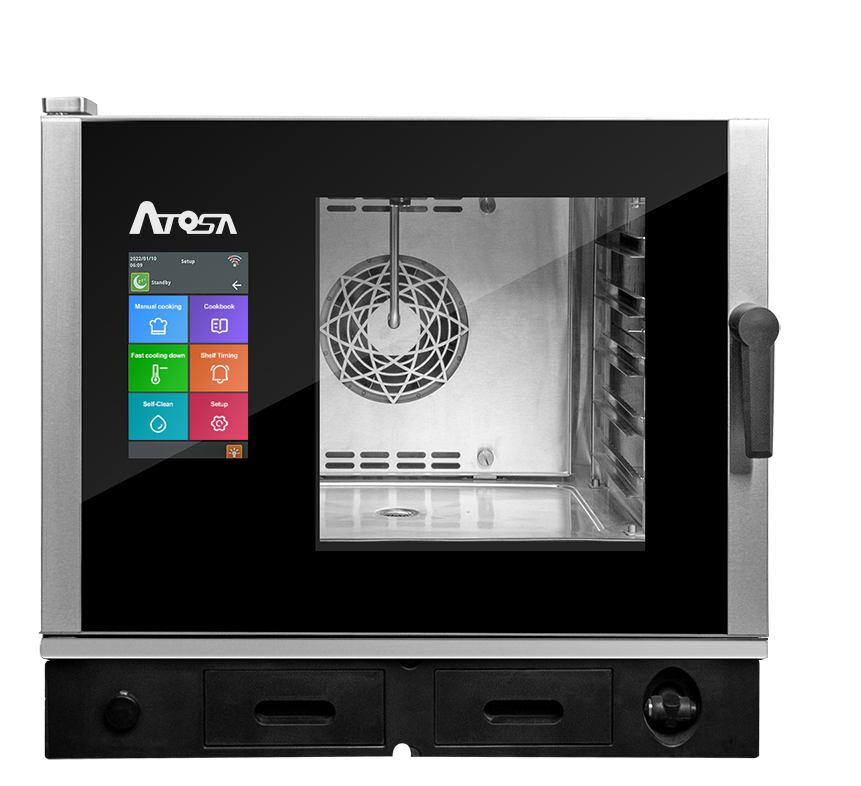

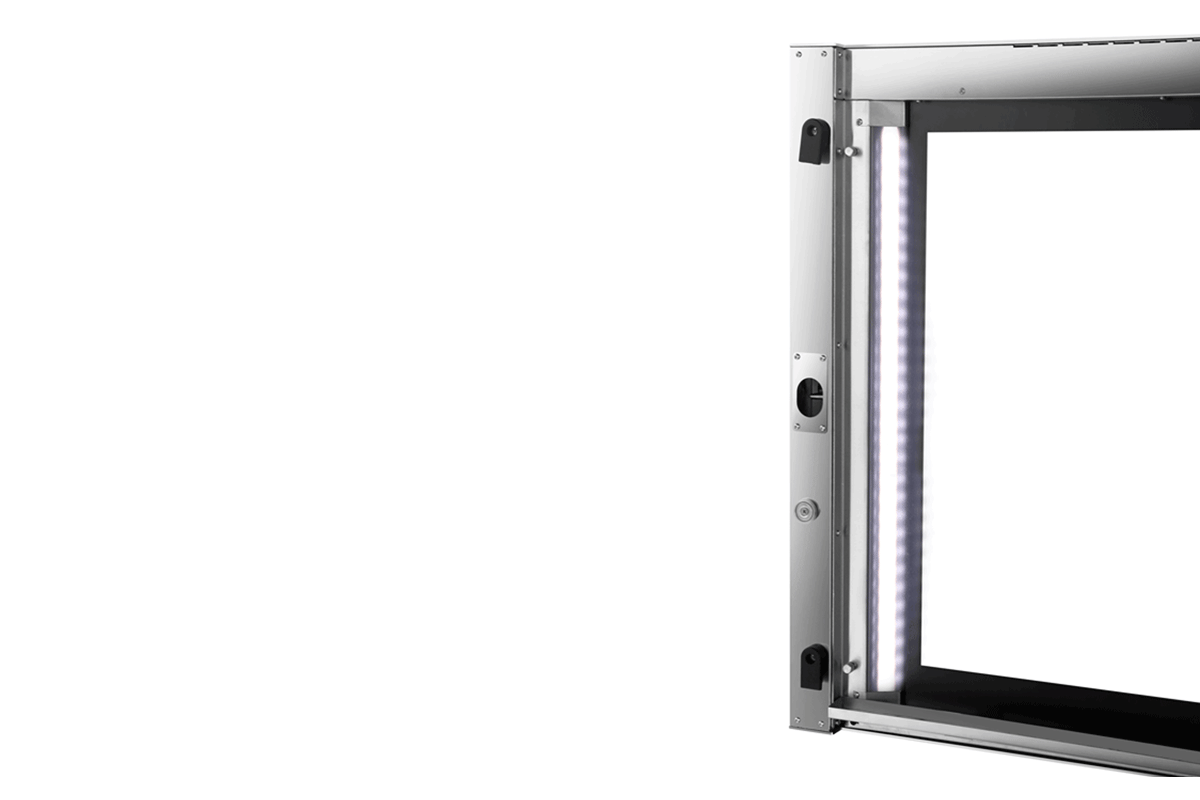

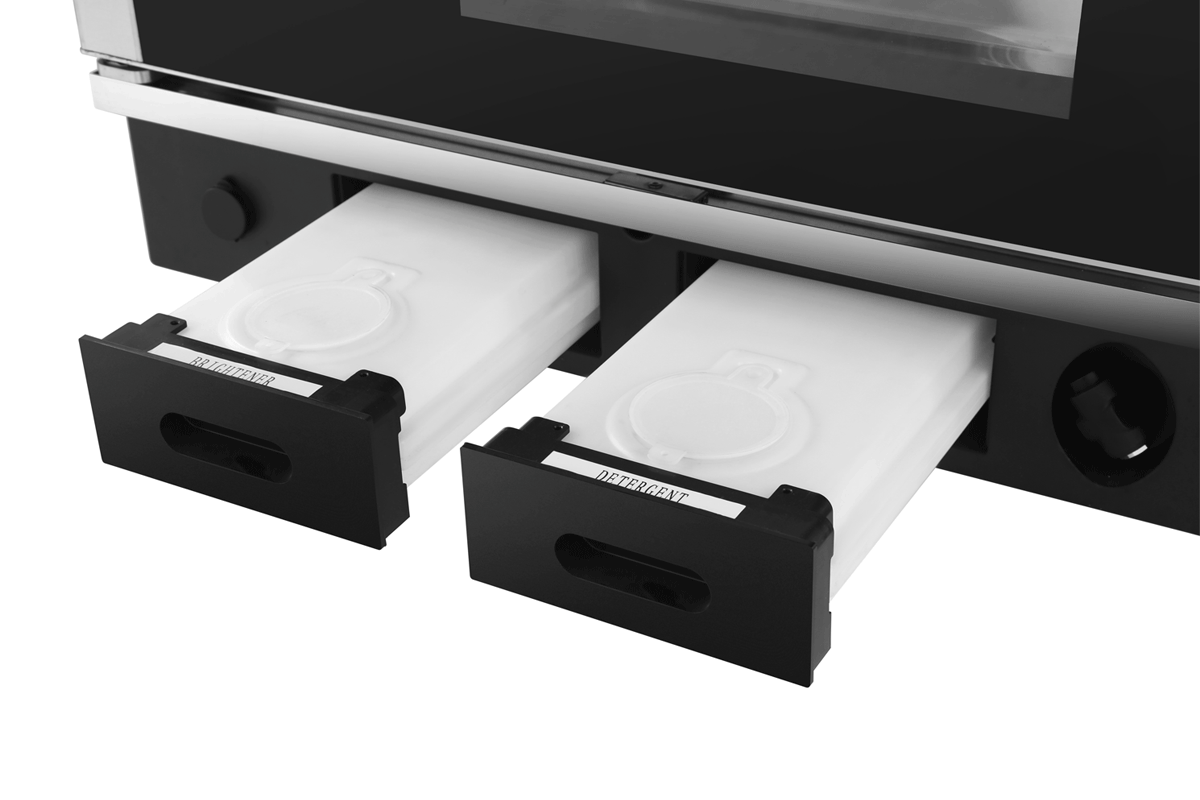

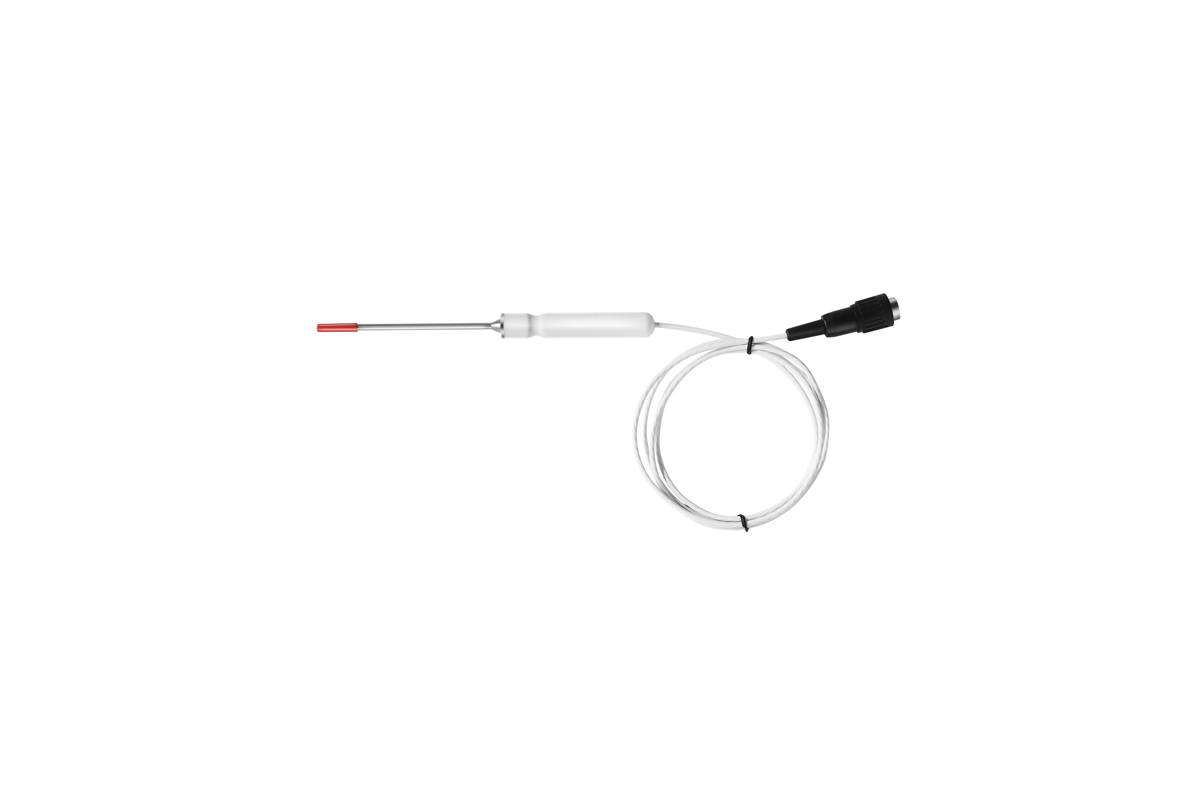

The ATOSA EPC-0511E1 Commercial Convection Oven revolutionizes the professional kitchen with state-of-the-art technology and innovative features. Ideal for catering, bakeries, and patisseries, this convection oven with 5 GN1/1 levels offers maximum precision and efficiency. Thanks to Smart Cooking technology, a responsive 10-inch touchscreen, and Wi-Fi connectivity, you can master any culinary challenge – from à la carte service to banquets.

Interested? Get advice now!

The ZERMAT Heat Sealing Machine TBG is the ideal solution for hygienically sealing food in trays. Perfect for butcher shops, gastronomy businesses, catering companies, and food manufacturers who value quality, durability, and clean presentation.

Interested? Contact us for personalized advice!

The TBG PLUS is the advanced version of the proven ZERMAT TBG. It offers the highest precision in sealing trays for fresh or prepared foods – ideal for gastronomy, food production, and catering.

Ready for the next level in food packaging? Contact us!

The JazzVac Mini is ZERMAT’s smallest professional vacuum packaging machine. It is perfect for kitchens, small shops, labs, or sales outlets with limited space.

The perfect solution for small businesses – contact us!

The BluesVac 52 is a powerful tabletop vacuum packaging machine, ideal for butcher shops, gastronomy businesses, and delicatessen stores. With a robust stainless steel construction and advanced features for reliable performance.

Optimize your packaging processes – contact us!

The ZERMAT CV100 is a powerful double-chamber vacuum packaging machine for industrial use. It impresses with reliability, speed, and hygienic design.

Boost your production capacity – contact us!

The ZERMAT CV200 is ideal for businesses with medium production volumes. It combines powerful technology with user-friendly operation and is entirely made of stainless steel.

Efficient packaging for your business – contact us!

The ZERMAT CV1000 is a chamber vacuum packaging machine from the Medium series, ideal for larger productions with high demands for performance, hygiene, and flexibility.

High performance for your production – contact us!

The ZERMAT DC750 is an industrial vacuum packaging machine with a double-chamber system, designed for maximum efficiency in high production environments. Ideal for the food industry.

Maximum efficiency for your production – contact us!

The DC950 is the flagship of ZERMAT’s LARGE series, designed specifically for the highest production volumes in the food industry. With a robust design and a 300 m³/h vacuum pump.

The best for your large-scale production – contact us!

The Nowicki Automatic Angle Mincer is designed for grinding frozen meat blocks down to -22°C. Recommended for large meat, fish, and pet food processing plants with high efficiency and hygienic design.

| Model | W-200B | W-280B |

|---|---|---|

| Throughput | High throughput | High throughput |

| Material | Stainless steel | Stainless steel |

| Temperature Range | Down to -22°C | Down to -22°C |

Interested? Get advice now!

The MADO Automatic Mixing Mincer MEW-724-D114-E52 is a versatile meat mincer for professional meat processing. With a robust design and modern technology, it enables precise mixing and grinding of meat, ideal for butcher shops and catering.

| Feature | Value |

|---|---|

| Material | Entirely stainless steel |

| Motor | Powerful two-speed motor |

| Cutting Set | Unger D114 5-piece or Enterprise Size 52 |

| Options | Cooling, separating set, stainless steel worm |

Interested? Get advice now!

The MADO Extruder Mincer MMG 233-U200 is a powerful meat mincer for industrial meat processing. With a patented twin cutting system and modern control, it optimizes production for high throughput.

| Feature | Value |

|---|---|

| Material | Entirely stainless steel |

| Cutting Set | Patented twin cutting set, 5-piece |

| Control | Programmable control with touchscreen |

| Options | Automatic loading |

Interested? Get advice now!

The MADO Extruder Mincer MMG 235/239/243-U200 is a series of powerful meat mincers for industrial processing. With a patented twin cutting system and advanced features like a cleaning platform, it optimizes production for the highest demands.

| Feature | Value |

|---|---|

| Material | Entirely stainless steel |

| Cutting Set | Patented twin cutting set, 5-piece |

| Control | Programmable control with touchscreen |

| Options | Automatic loading, cleaning platform |

Interested? Get advice now!

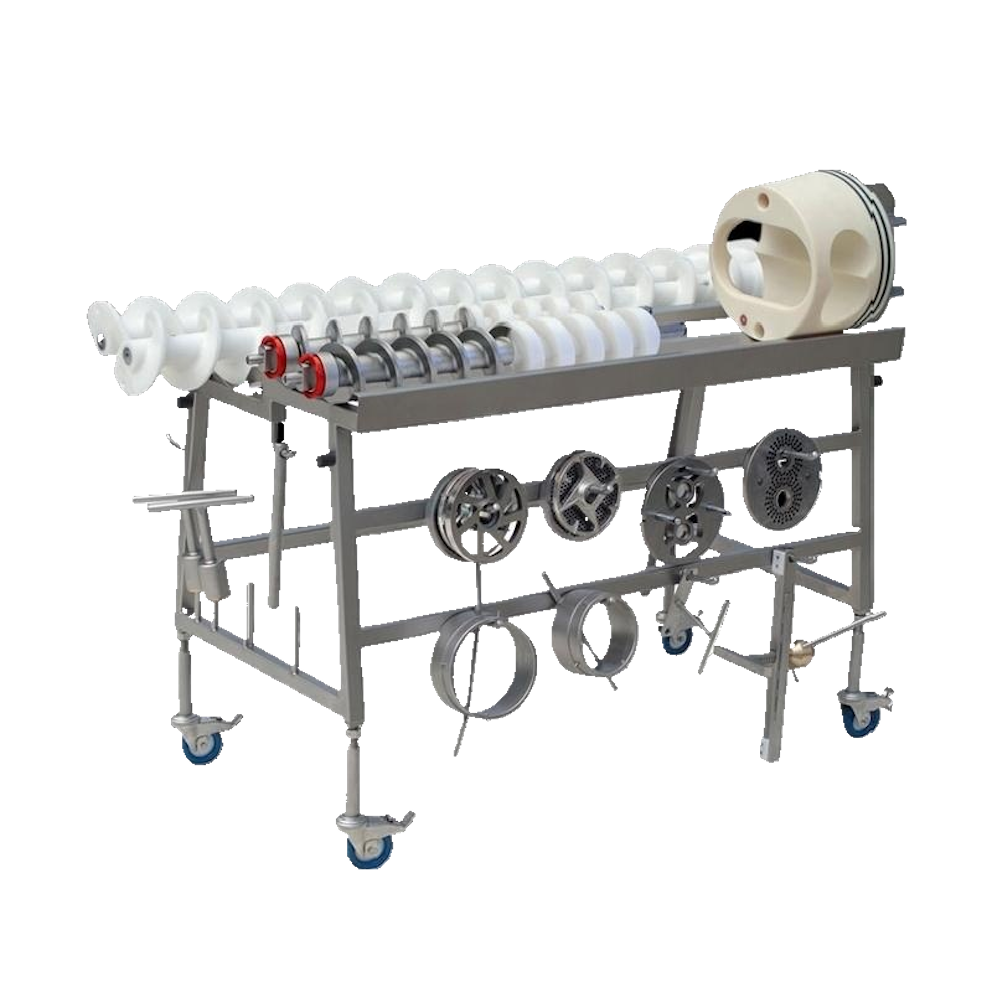

The MADO Tool Cart is the ideal accessory for your meat mincers. It enables easy storage and organization of tools and accessories, made of robust stainless steel.

Interested? Get advice now!

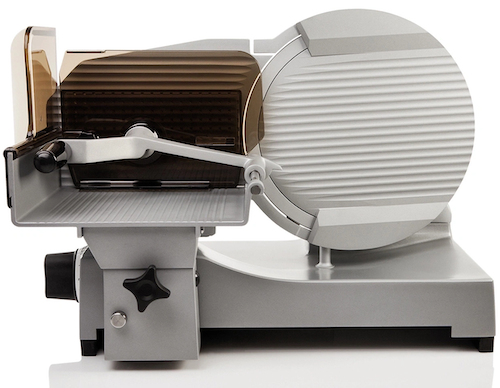

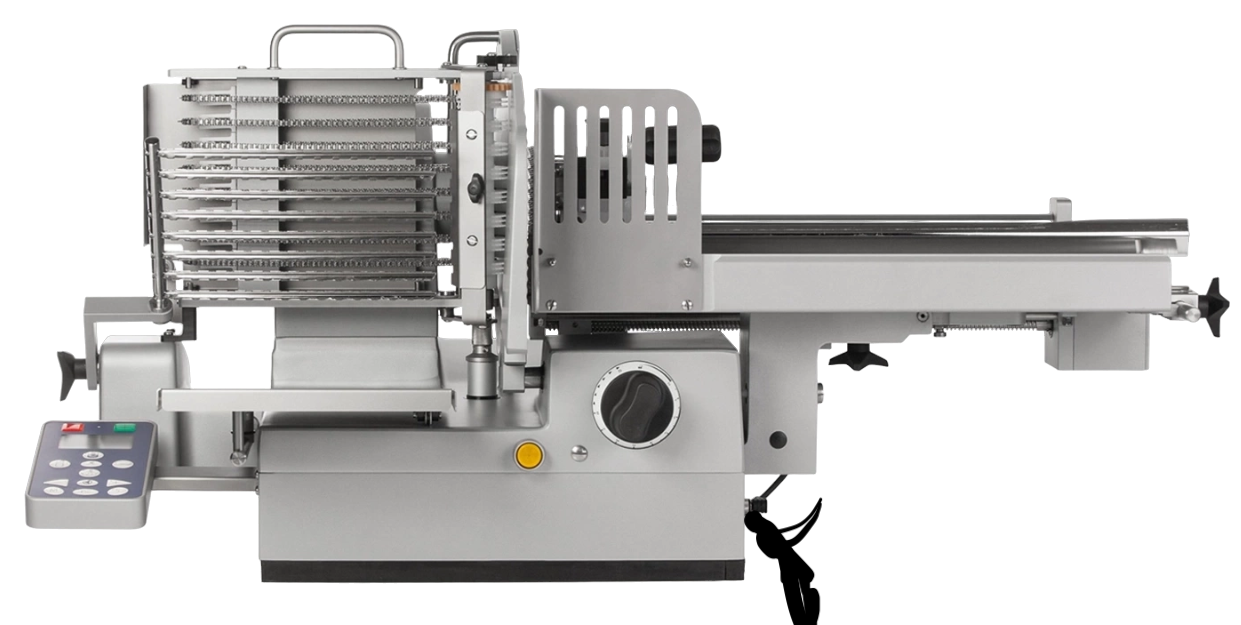

The Graef Master 3020 is a versatile slicer with a Ø 300 mm blade and precise slice thickness (0–24 mm), ideal for continuous use in butcher shops or gastronomy. It combines ergonomics with high performance and easy cleaning. Available in multiple variants: standard carriage, thin-slice carriage (TS), salmon carriage (SC), Vario Slice (VS), and with integrated scale (W).

Ready for efficiency? Contact us!

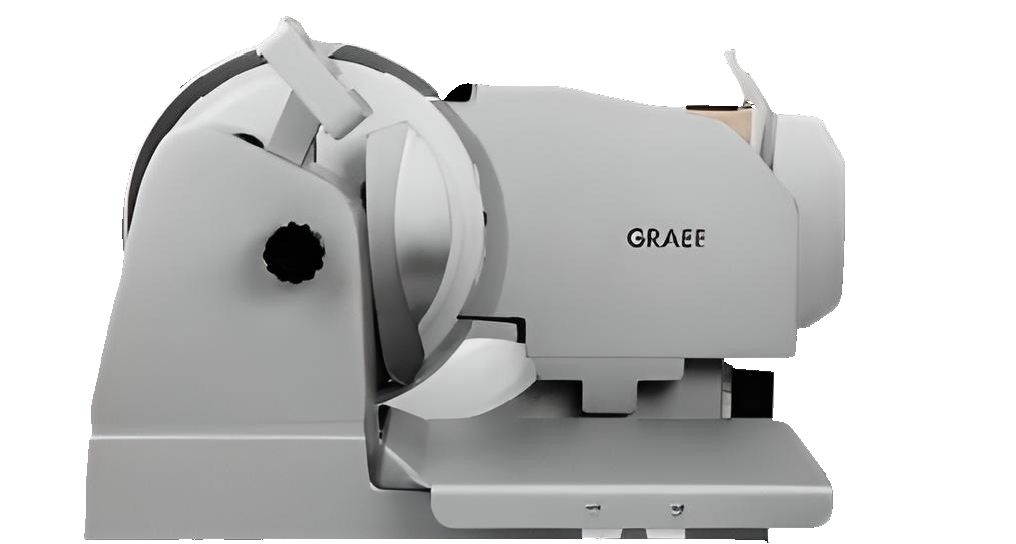

The entry into the MASTER Line. Due to its compactness and quality, it’s the solution for small spaces. Also ideal as a counter machine. The Graef Master 2720 is the perfect slicer for counter use. With a maintenance-free motor and CERA-3 coating, it guarantees precise cutting and easy cleaning – ideal for butcher shops, gastronomy, and catering.

Interested? Get advised now!

The Master 3310W optimizes your workflow with an integrated scale (0–5000 g). Perfect for precise cutting and weighing in one step – ideal for butcher shops and production. Available in multiple variants: standard carriage, double carriage (DC), clamping arm carriage (CA), and version with scale (W).

Curious? Get advised!

The Master 3370 with an 18° tilted carriage securely fixes the cutting material and simplifies operation. Ideal for fast, precise work in production.

Interested? Ask for details!

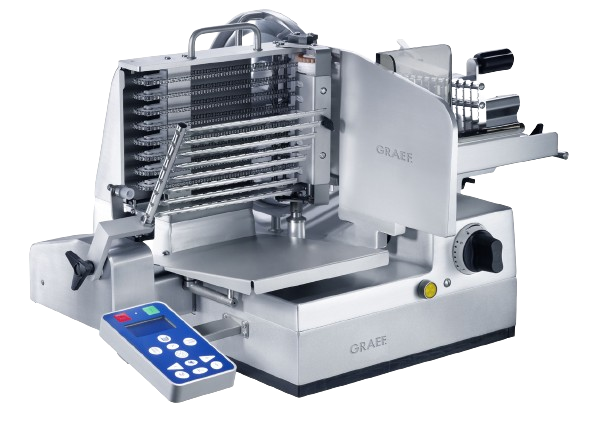

The VA 802 (optionally VA 802H with semi-automatic mode) is a fully automatic slicer with a 500 Watt motor and Ø 300 mm blade. Ideal for butcher shops and buffets, it offers continuous operation and precise cuts (0.5–10 mm).

Want to test it? Ask about a demo machine!

The VA 804 offers maximum efficiency with a Ø 300 mm blade and 500 Watt motor. Its tiltable carriage simplifies cleaning – perfect for demanding productions.

Ready for more? Contact us!

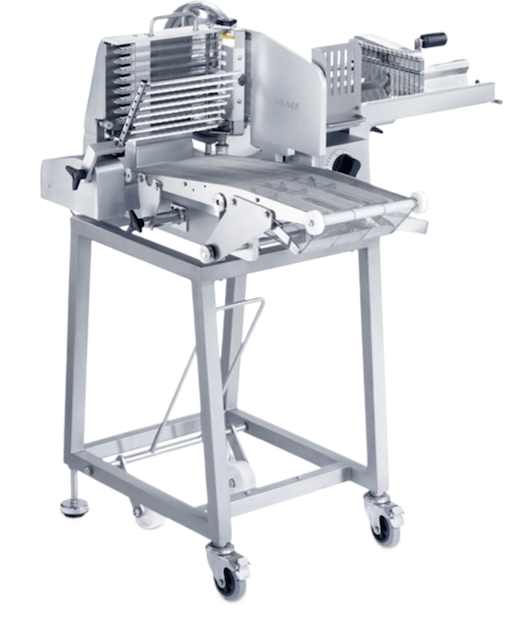

The VA 804FB with conveyor belt and rollers is the ultimate solution for large-scale productions. With 500 Watt and a Ø 300 mm blade, it cuts precisely and efficiently.

Boost efficiency? Get advised!

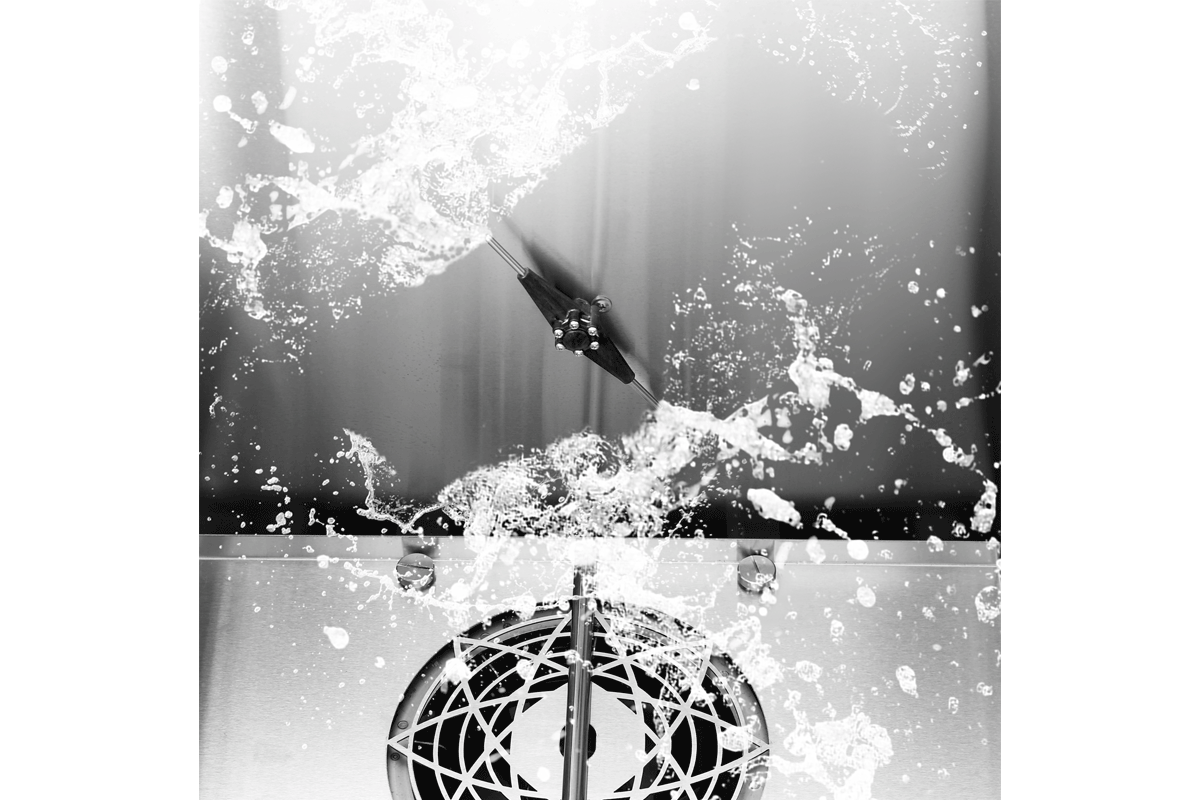

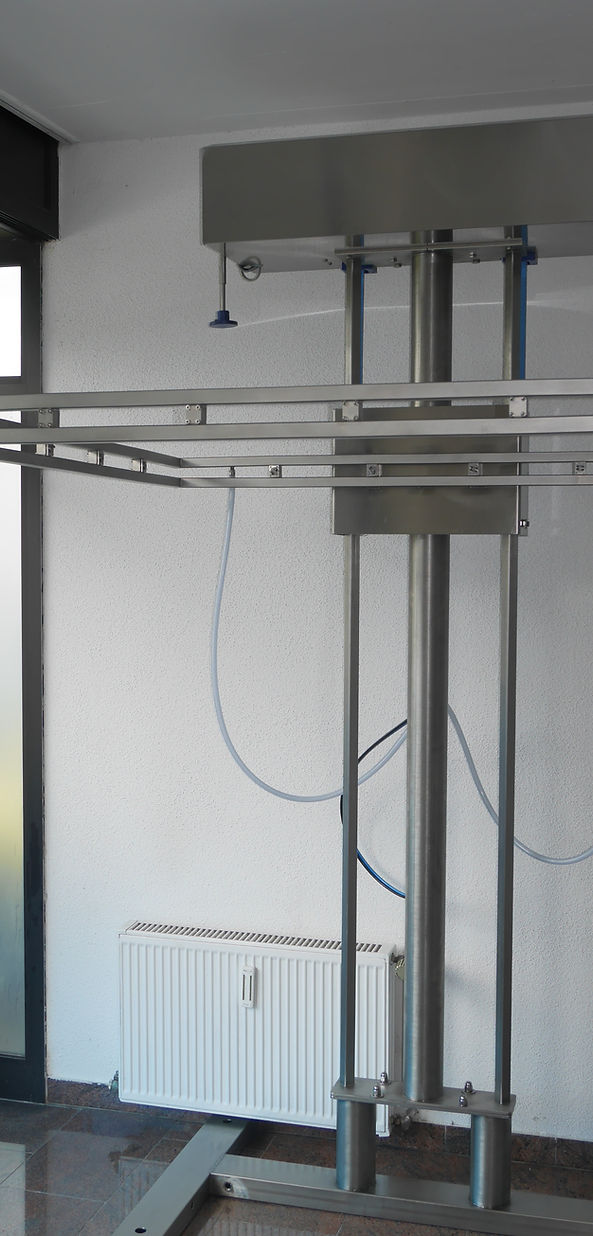

Discover WUDU, the eco-friendly alternative to conventional sausage showers. With up to 95% water savings and innovative evaporative cooling, WUDU offers maximum efficiency and quality for your products. Let us advise you!

Experience the revolution in cooling technology with WUDU – eco-friendly, efficient, and sustainable. Save up to 95% water and optimize your production processes.

Interested? Let us advise you now!

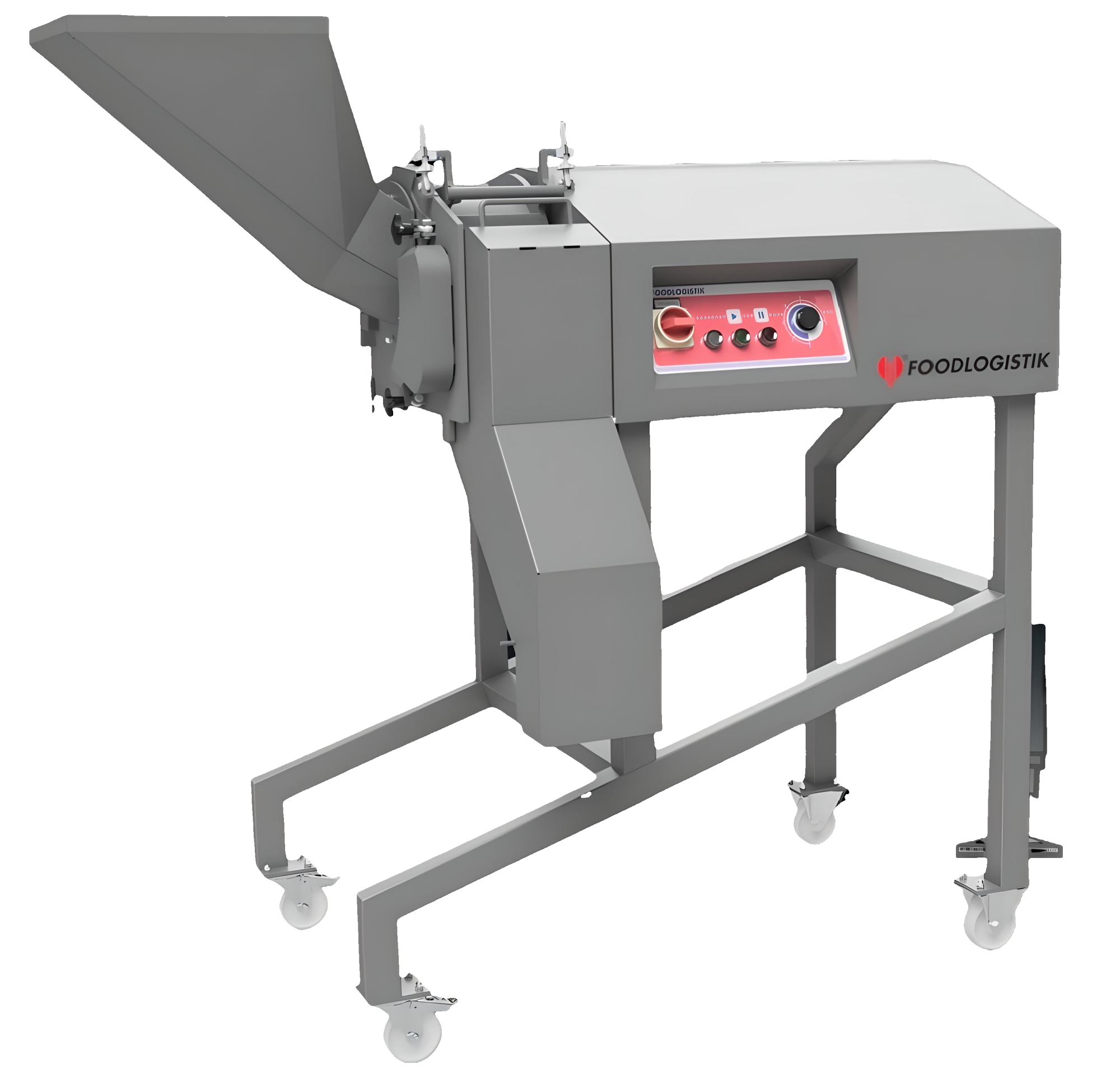

The Shreddr is optimized for continuous cutting of vegetables and fruits into cubes, strips, and slices. Its robust design and easy cleaning make it ideal for continuous operation.

Optimize your processing! Contact us!

The Trenn-Fix 2.0 from Heinrich GmbH is the cornerstone for precise sausage separation. With patented technology and high flexibility, it optimizes your production and saves valuable working time.

| Feature | Value |

|---|---|

| Throughput | Up to 3,000 kg/h (depending on product) |

| Sizes | 3 different sizes available |

| Application Range | Sausages from 3 g to 300 g |

| Hygiene | Integrated cleaning program |

| Safety | Safety switch for infeed/outfeed |

Interested? Contact us for a tailored offer!

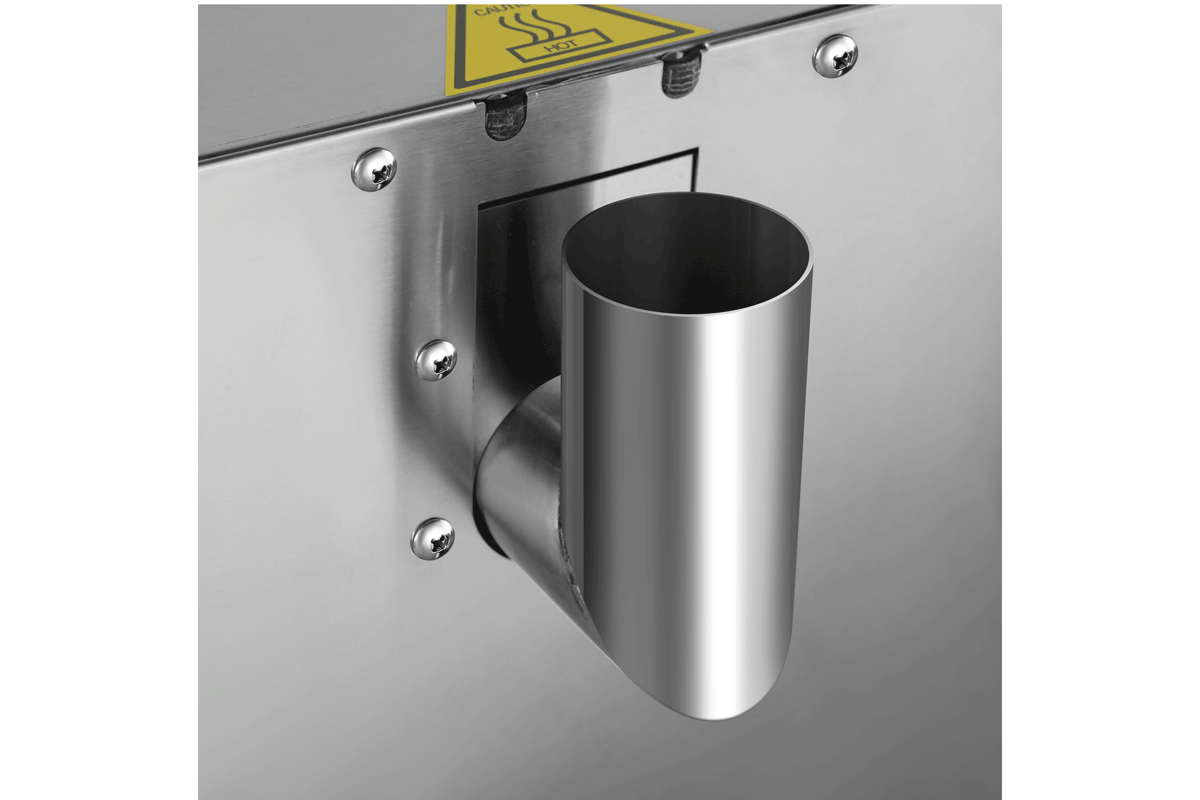

NOMA Nowicki crate washing machines (e.g., MP-300 and MPU-600) deliver optimal cleaning results for plastic crates, lids, and Euro pallets. With modular design and cutting-edge technology, they are ideal for the food industry.

| Feature | Value |

|---|---|

| Throughput | Up to 600 crates/h (MPU-600) |

| Modularity | Optional pre-wash and air blow-off modules |

| Water Circulation | Closed, with rinse intensity control |

| Heating Systems | Electric, steam, gas, oil, hot water |

| Operation | Touchscreen control panel |

| Safety | Protection against unintended opening |

Interested? Contact us for a tailored offer!

Discover an innovative solution for your smoking processes: The electrically heated smoking chamber Model 850 uses state-of-the-art smoke condensate atomization via compressed air. Let the benefits of this technology convince you!

With these features, you’re ready to go:

Make the Model 850 your perfect solution with these optional highlights:

Curious? Contact us for personalized consulting!

Experience the perfect combination of efficiency and flavor: The Model 851 is an electrically heated smoking system with a cleverly integrated wood chip smoke generator in the door. Be inspired by this space-saving solution!

These features ensure a smooth start:

Customize the Model 851 to your needs with these optional extras:

Interested? Let’s find your perfect solution together!

Experience maximum efficiency and quality: The Bastramat Model 1201 RR is a versatile smoking system with an integrated friction smoke generator in the door. This solution offers flexibility for various heating types and delivers outstanding results!

These features ensure a reliable start:

Make the Model 1201 RR your tailored solution with these options:

Interested? Contact us for personalized consulting!

Experience professional smoking at the highest level: The Bastramat Model 1501 UF/GS is a versatile smoking system with an integrated sawdust smoke generator in the door. This solution offers flexibility and top-notch results for various heating types!

These features ensure a reliable start:

Make the Model 1501 UF/GS your tailored solution with these options:

Interested? Contact us for a tailored offer!

Experience professional smoking technology at the highest level: The Bastramat Model 2000 TF is a powerful smoking system with a standalone wood chip smoke generator, distinguished by flexibility and top-notch results. Ideal for large-scale productions!

These features ensure a reliable start:

Make the Model 2000 TF your tailored solution with these options:

Interested? Contact us for a tailored offer!

Bring flavor and versatility directly to your counter! The Smart 500 by BASTRA is the perfect universal system for classic smoked goods and more – whether cold or hot smoking, heating, drying, cooking, or roasting. With intuitive operation and patented smoke condensate technology, smoking has never been easier. Get inspired!

| Feature | Value |

|---|---|

| Heating Type | Electric |

| Smoke Generator | Clean Smoke |

| Dimensions (W×D×H) | 980×1020×2000 mm |

| Minimum Required Room Height | 2020 mm |

| Chamber Capacity | 430 Liters |

| Minimum Required Door Width | 1100 mm |

| Smoke Stick Length | 570 mm |

| Load Capacity | 35–110 kg |

| Heating Power | 15 kW |

Ready for the next step in your kitchen? Contact us and explore the possibilities!

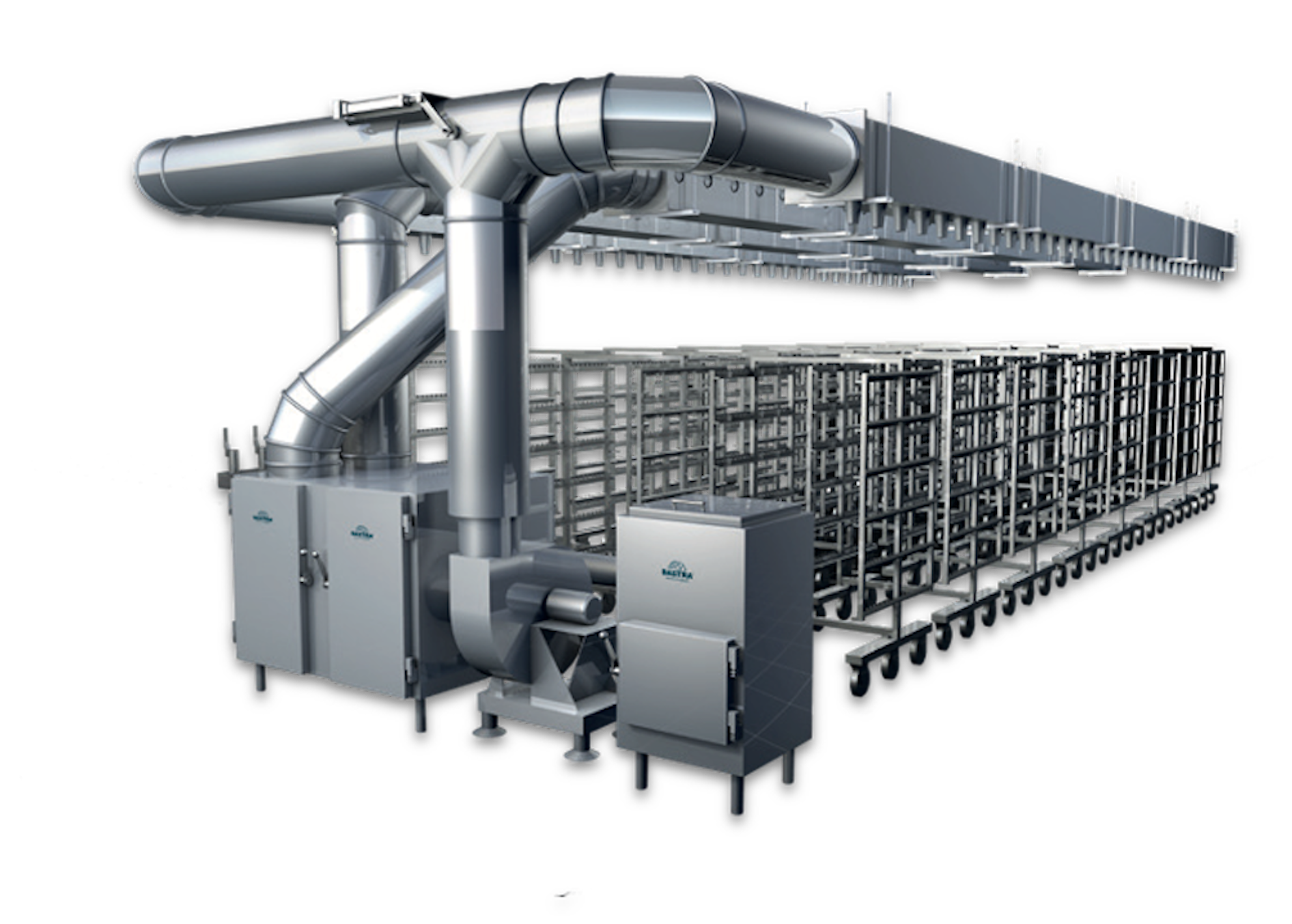

Give your raw and long-life products an unparalleled flavor! BASTRA’s Climate Maturing Smoking Systems are your solution for precise maturing, drying, smoking, and post-maturing. Thanks to state-of-the-art technology, they create an ideal climate for a gentle maturing process – with plenty of space. Discover how your products can reach new heights!

Adapt the system to your production:

Ready for top-notch results? Contact us for your tailored solution!

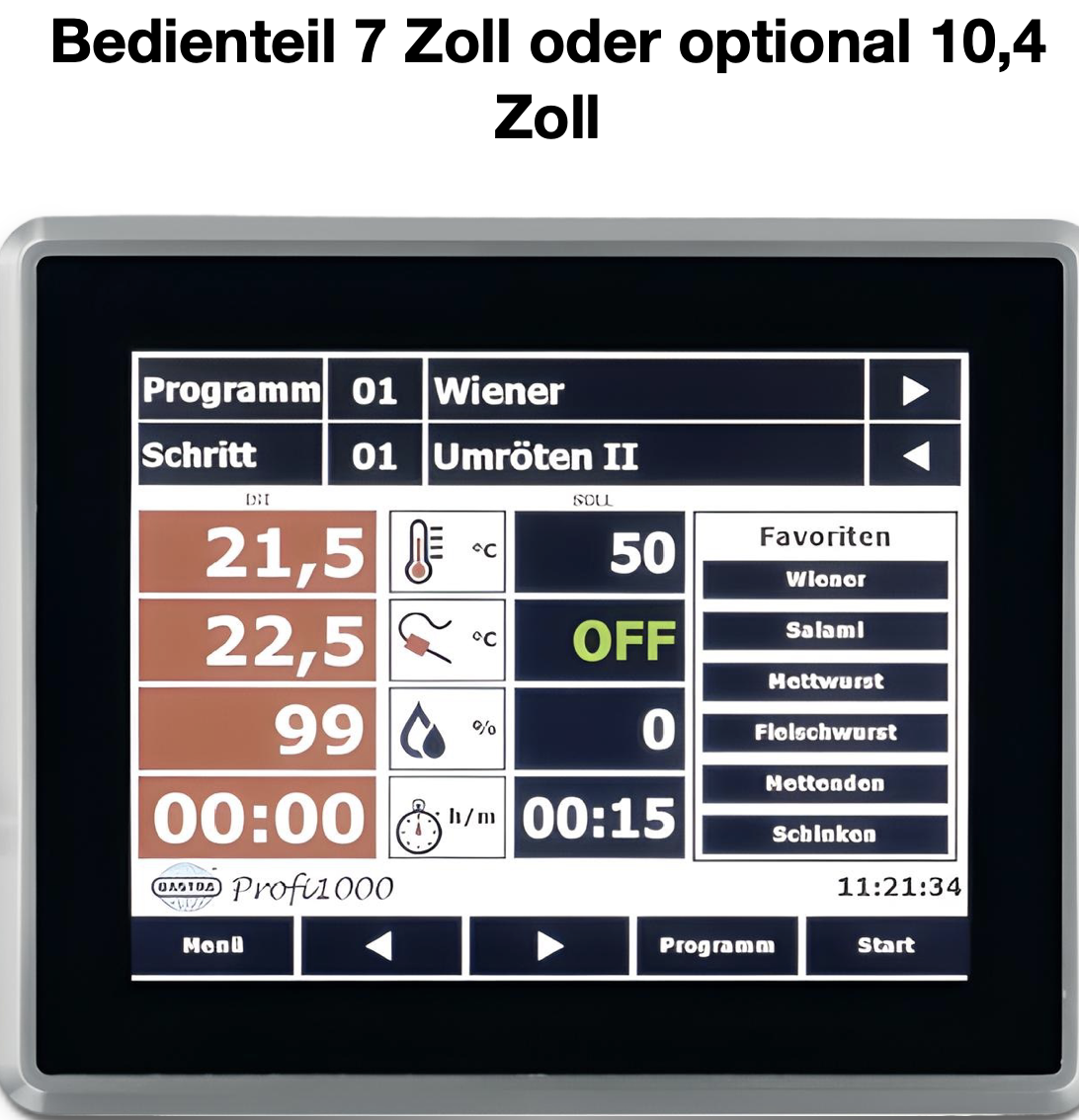

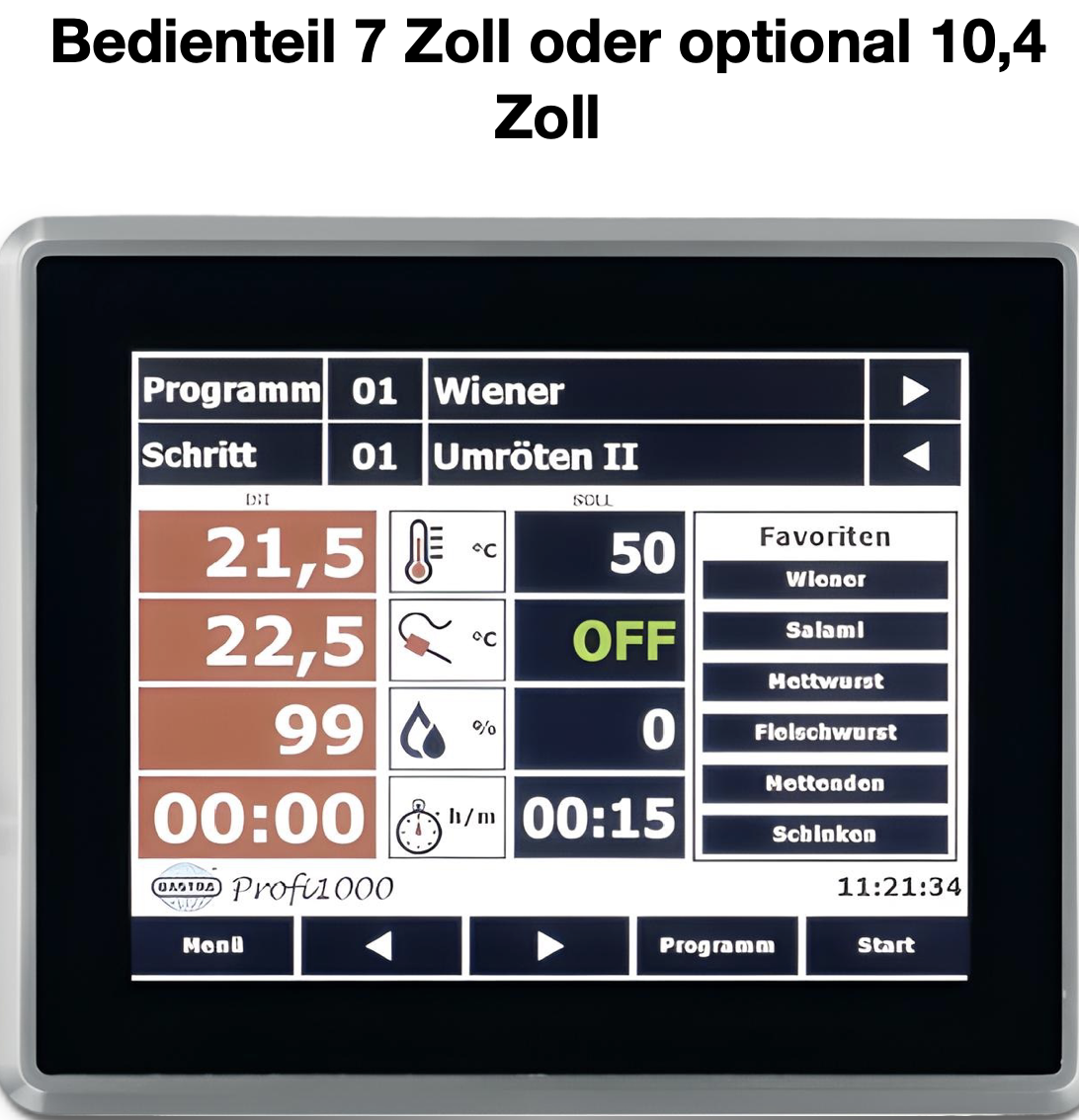

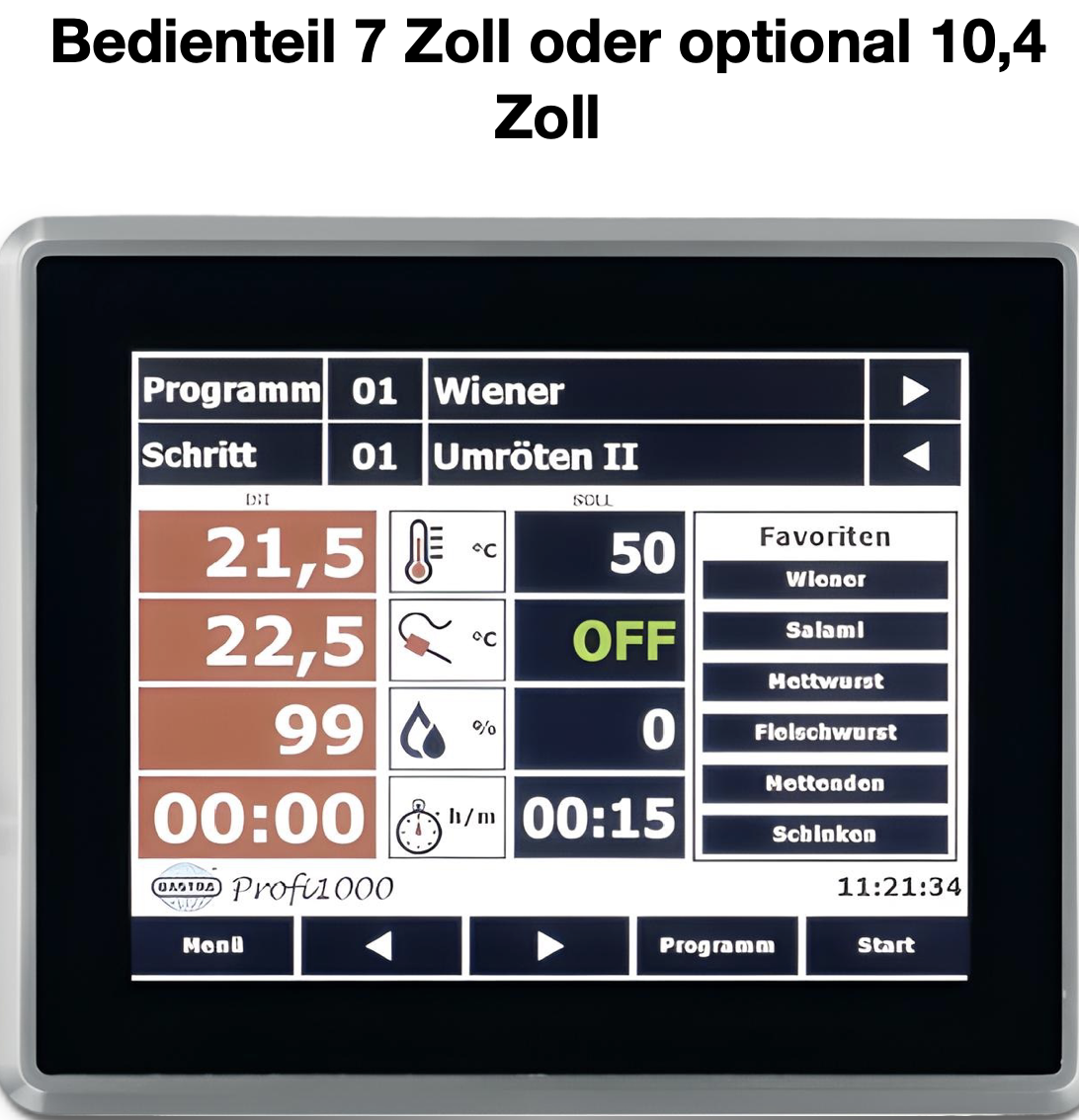

This cutter features a programmable control system that enables the management of recipes and processing steps. All target values are entered via a user-friendly touchscreen display. The shutdown can be set based on either temperature or the number of bowl revolutions.

Interested? Contact us for more details!

Interested? Contact us for more details!

This cutter is equipped with a touchscreen display that allows the input of all target values. The display shows indicators for knife shaft speed, number of bowl revolutions, temperature, and shutdown settings for temperature and bowl revolutions.

Interested? Contact us for more details!

Interested? Contact us for more details!

Achieve precise cutting results with our industrial cutters, ideal for producing sausages and other meat products.

Interested? Contact us for more details!